1. Product Definition & Concept

The UDR seal is a compact, uni-directional, single-acting rod seal designed for hydraulic and pneumatic cylinders. It integrates a primary sealing lip and an anti-extrusion ring into a single, space-saving unit, delivering high performance and reliability in demanding applications.

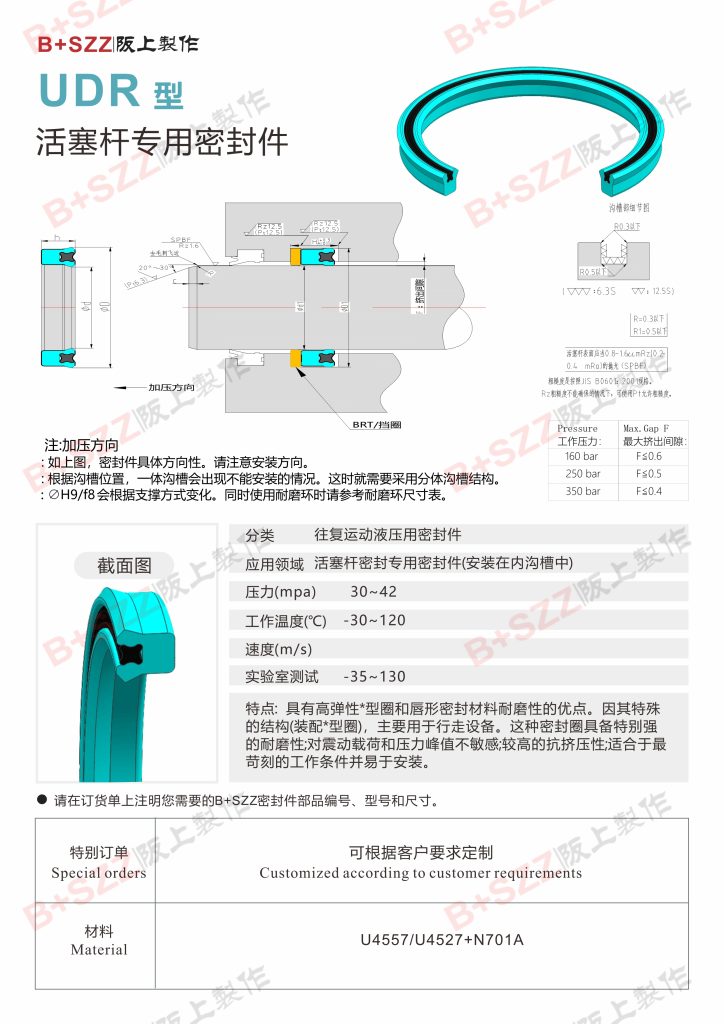

2. Design & Construction

The UDR features a patented two-component design:

Primary Sealing Element: A precision-molded polyurethane (PU) or nitrile rubber (NBR) lip with a symmetrical U-shaped profile. This lip generates optimal contact pressure against the rod, ensuring a tight seal across a wide pressure range.

Integrated Anti-Extrusion Ring: A rigid POM (Polyoxymethylene) or reinforced PTFE ring mechanically bonded or fitted into the heel of the sealing lip. This ring provides critical support to prevent lip deformation and extrusion into the rod-gland clearance under high pressure or large gaps.

3. Key Features & Advantages

Superior Leakage Control: Excellent sealing performance from low to high system pressures due to the self-energizing lip design.

High Pressure & Extrusion Resistance: The integrated support ring allows reliable operation at pressures up to 40 MPa (5800 psi) and in applications with dynamic gaps.

Reduced Friction & Wear: The stable support minimizes lip roll and distortion, ensuring smooth rod movement, lower breakout friction, and extended service life.

Simplified Installation & Inventory: A single-component design eliminates the need for separate backup rings, reducing assembly time, error, and part numbers.

Compactness: Ideal for modern cylinder designs with limited gland space.

4. Typical Applications

UDR seals are the preferred solution for rod sealing in medium to heavy-duty hydraulic equipment:

Mobile Hydraulics (Excavators, Loaders, Cranes)

Industrial Machinery (Injection Molding Machines, Presses)

Agricultural Equipment (Tractor Implements, Harvesters)

Marine and Offshore Actuators

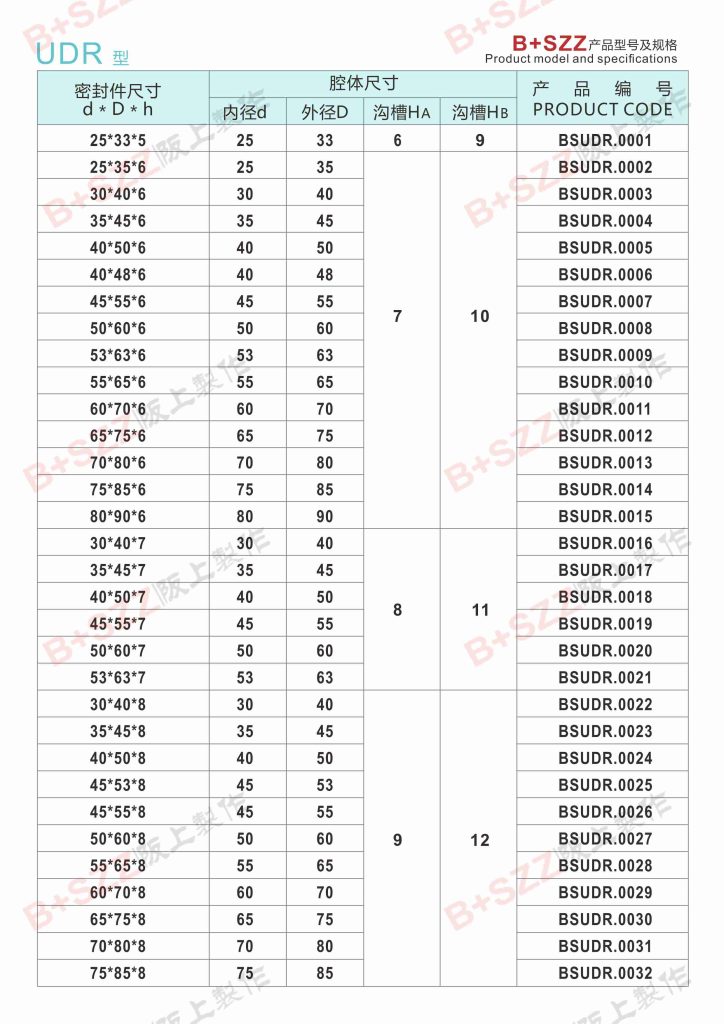

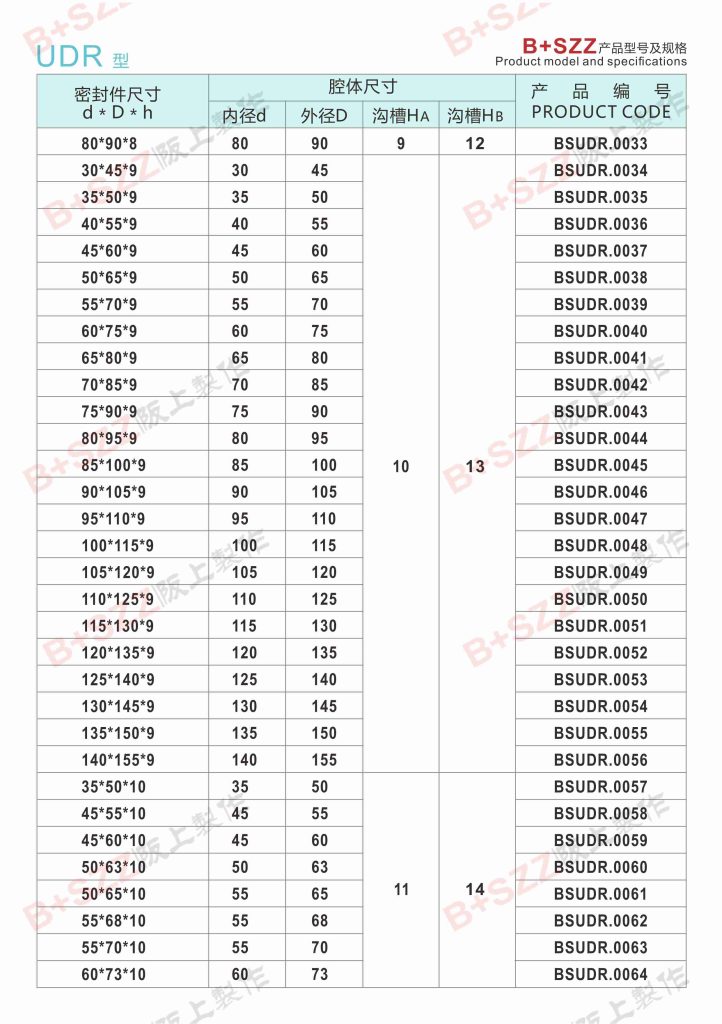

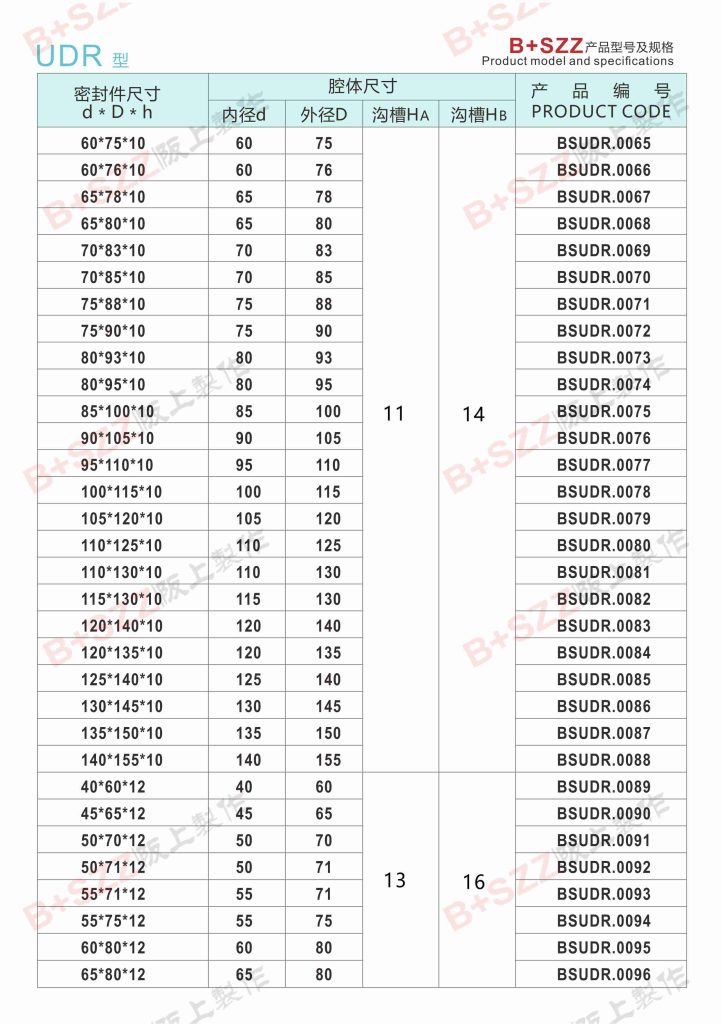

5. Technical Specifications & Selection Guide

Pressure Range: 0 to 40 MPa (static), 0 to 25 MPa (dynamic)

Temperature Range: -30°C to +110°C (for standard PU material)

Media Compatibility: Mineral-based hydraulic oils, HFA/HFB fluids, water-glycol, and lubricants. Special materials (e.g., FKM) available for phosphate esters or aggressive media.

Rod Speed: Suitable for low to medium reciprocating speeds.

Surface Finish: Recommended rod surface roughness: Ra 0.1 – 0.4 μm.

6. Installation & Gland Design

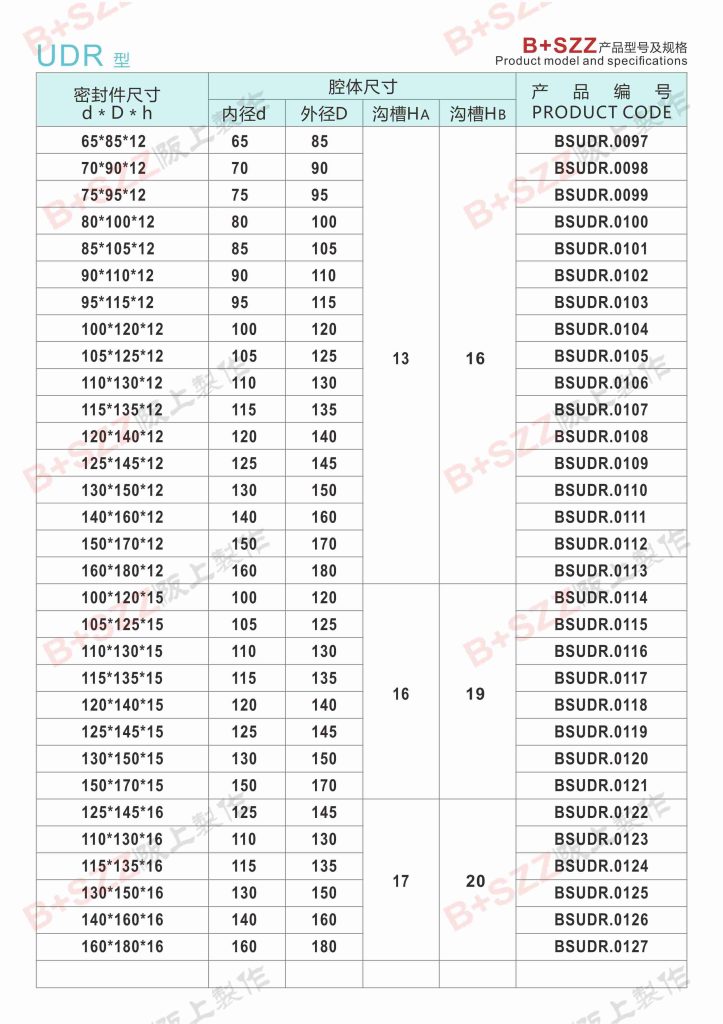

Gland Dimensions: Must conform to manufacturer specifications to ensure correct seal compression.

Chamfering: A generous 15°-20° chamfer with a smooth finish is mandatory on all leading edges to prevent lip damage during installation.

Installation Tools: The use of dedicated installation sleeves or cone tools is strongly recommended to guide the seal into the gland without lip inversion.

Lubrication: Always lubricate the seal and rod with the system fluid prior to assembly.

7. Material Options

Sealing Lip: Standard: Polyurethane (AU/EU). Alternatives: NBR (cost-effective), FKM (high temp/chemical resistance).

Anti-Extrusion Ring: Standard: POM. Alternatives: Glass-filled PTFE (for lowest friction), PEEK (for highest temp/chemical resistance).

Why Choose the UDR Seal?

The UDR rod seal represents an optimal balance of performance, durability, and design efficiency. Its integrated construction solves traditional sealing challenges—extrusion, complex installation, and space constraints—making it a robust and reliable choice for next-generation cylinder design.

Original source: Hydraulic seal https://www.bszzseal.com/